Lemmy Shitpost

Welcome to Lemmy Shitpost. Here you can shitpost to your hearts content.

Anything and everything goes. Memes, Jokes, Vents and Banter. Though we still have to comply with lemmy.world instance rules. So behave!

Rules:

1. Be Respectful

Refrain from using harmful language pertaining to a protected characteristic: e.g. race, gender, sexuality, disability or religion.

Refrain from being argumentative when responding or commenting to posts/replies. Personal attacks are not welcome here.

...

2. No Illegal Content

Content that violates the law. Any post/comment found to be in breach of common law will be removed and given to the authorities if required.

That means:

-No promoting violence/threats against any individuals

-No CSA content or Revenge Porn

-No sharing private/personal information (Doxxing)

...

3. No Spam

Posting the same post, no matter the intent is against the rules.

-If you have posted content, please refrain from re-posting said content within this community.

-Do not spam posts with intent to harass, annoy, bully, advertise, scam or harm this community.

-No posting Scams/Advertisements/Phishing Links/IP Grabbers

-No Bots, Bots will be banned from the community.

...

4. No Porn/Explicit

Content

-Do not post explicit content. Lemmy.World is not the instance for NSFW content.

-Do not post Gore or Shock Content.

...

5. No Enciting Harassment,

Brigading, Doxxing or Witch Hunts

-Do not Brigade other Communities

-No calls to action against other communities/users within Lemmy or outside of Lemmy.

-No Witch Hunts against users/communities.

-No content that harasses members within or outside of the community.

...

6. NSFW should be behind NSFW tags.

-Content that is NSFW should be behind NSFW tags.

-Content that might be distressing should be kept behind NSFW tags.

...

If you see content that is a breach of the rules, please flag and report the comment and a moderator will take action where they can.

Also check out:

Partnered Communities:

1.Memes

10.LinuxMemes (Linux themed memes)

Reach out to

All communities included on the sidebar are to be made in compliance with the instance rules. Striker

view the rest of the comments

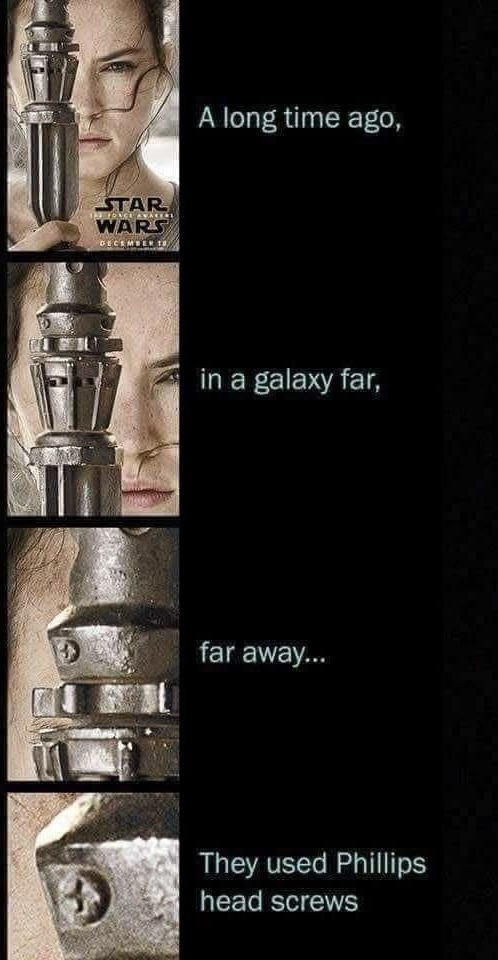

I feel like a + shaped screw head would be as standard as a pyramid if multiple civilizations had developed screws independently. It wouldn't be the last kind, but it would be there somewhere. Maybe even a long, long time ago.

There are at least 3 standards for the + shape already. Phillips, Pozidrive, and Japanese Industrial Standard (JIS). They do not play well together.

insert obligatory xkcd standards reference

Don't forget Frearson/Reed & Prince!

But wait, there's more!

And even more!

We only have standards so we can break'em.

JIS has been obsoleted and replaced in Japanese products with the ISO Phillips bit shape. It still exists on lots of products pre 2000 though.

Kawasaki is still holding on strong to JIS screws in it's machinery.

Are you sure they're JIS? Because JIS and ISO are interchangeable and effectively the same; the ISO adopted standard used most of JIS's rules.

Yeah. I keep one of these around just for older Yamaha and newer Kawasaki equipment. You'll end up drilling half of them out if you try to use #3 ISO.

I'm in the powersports/agricultural industry, so we tend to lag behind everyone else.

That's just galvanic corrosion from using cadmium plated bolts in aluminum fuel injection hardware. It's basically free loctite.

JIS is looking better according to these guys…

This bugs me so much more than it should. Why do we have three different standards for + shaped screws? You know what doesn't have this problem? Flatheads. There's exactly one way to make a flathead screwdriver, and I won't be looking it up to make sure I'm right

I see that multiple people have replied, but unfortunately reading these comments would be a form of research so I must decline

Should the slot be partial or go all the way through? If partial, is that standard for the size of the screw, or universal?

How wide should the slot be? Should that change based on the size of the screw?

How deep should the slot be?

Should the sides of the slot be perfectly straight, or angled to perfectly fit the wedge shape of the driver? If angled, what angle?

Should the bottom of the slot be perfectly flat or slightly rounded so a coin or something could be used in a pinch? If rounded, what radius?

Should the top of the screw be perfectly flat, or domed, or raised?

Should the bottom of the head be flat, angled (at which angle), smooth, rough.

Should we use metric or freedom units for the thread pitch?

Should the threads go all the way to the head?

Should the point of the screw be flat or tapered (at what angle)?

Ok, only the first half of those were about the driver used, but I'm sure there are things I missed in that!

Their isn’t one way to make a flat head screwdriver. Some a chisel and some are slots. The slotted ones are better but more expensive.

Both still slip from the screw and are a pain to manually screw (slotted less so).

Pozi is the best + type screw. It’s pretty much standard for UK construction. The only time a different type is used is sometimes Phillips for plaster board or external hex and internal torx for long or large screws.

I think a single slotted screw head would be more universal and easy. You just cut one line into the top of the screw head and your ready to go. A Philips head would need to be cut twice and once you did, you've weakened the head one degree more by removing more material

You clearly haven't had to screw a flathead screw.

Anyone that's dicked around with those little bastards starts hating life after about thirty seconds. A fastener I can screw in a without having to be perfectly in line with the shaft? Yes please! I don't care if it's a shitty Phillips screw, sign me up. I'd even take those goofy square Canadian screws. Hell, anything is better than flathead.

I challenge you to find a screw worse to use than a flathead screw.

In my experience, Phillips heads strip more often than Robertson.

Torx > Hex > Robertson > Pozidriv > Phillips > Slot.

This is not (just) the ramblings of a mad nerd, but objective fact derived from contact area between screwdriver and screw.

In practice hex does have one situational advantage over Torx, namely that they are almost always tightened with Allen keys which are more torque-y and can be used in tight spaces. For every other application Torx wins. Every other head type is strictly inferior and only exists for legacy or penny-saving reasons.

What they don't say is that the smaller the features on the contact, the easier it is to strip them. This almost reverses the order on your post depending on the way you tighten the screw.

For hex yes, for Torx no. Your smartphone's itty bitty screws are quite possibly T4 or similar.

Torx is more resilient to over-torsion than Hex, but both of them will end near the end of the list on that one metric, with slot first, and way ahead of anything else.

Despite what the Torx publicity says, engineering is done over a multitude of dimensions, and that one dimension Torx wins may not be nearly as important as some other random one.

Ngl if I didn't have impact drivers I'd probably hate Phillips screws a whole lot more

Obligatory 'yo momma'.

I agree ... and if I ever had the choice ... I'd go with Robertson or Torx for all my screws

But we were talking about (I thought that is what we were talking about) is what common basic screw design would be common to appear in a world where no screws existed. A slot is simple and easy to make ... just take a metal saw and cut one slot and voila you can turn it with a simple flat screwdriver head ... simple to make, simple to reproduce ... a pain in ass? yes? a universal torture device that will make your life miserable? yes?

But if we ever end up in a situation where we have no hardware stores, no manufactured supplies, no heavy machinery, no metal stamping equipment, no heavy duty presses then cutting a simple slot across the top of a threaded rod is the easiest way to make your own screwhead and start working with using your own homemade screw driver ... a pain in the ass? yes ... but at least you can screw things together after the world has ended.

How tf can hyperdrive exist but screws haven't been invented lol

I think the real issue is that prop design has fallen so far from the ILM heyday. Now it's best described as follows:

This probably doesn’t exist but is probably worse the a flat head. What about a friction screw where the top is like rubber and to unscrew you need to rotated using a driver with another flat rubber head

So ironically I’ve used a rubber band similar to what you describe to break free and remove screws on several occasions. It’s not fool proof but worth a shot to avoid drilling and tapping.

Pics or it didn't happen

(lol just kidding. what you're describing is almost as bad as unscrewing a security flathead screw. look it up. invented by Satan, with help from Brian Thompson)

Easiest to manufacture tho (probably, I'm not an expert. But if you were to make a fastener with rudimentary tools, Phillips seems like it would likely be the easiest.)

Easiest, yes. And wheels are easier than repulserlifts. If sometime said "Ya know, greasing axels sucks balls. Let's invent something better", they probably developed something better than the shittiest screw head in the history of sentience.

But that's just, like, my opinion man

Ohhh no... As a person who regularly builds random shit for film and television, the single slotted screw is the bane of my bloody existence. Some designers fucking love em for the aesthetic but the cam outs on them are terrible. Is it technically easier to produce? Yes, is it viable to use for construction purposes comparitively - fuck no. Every time you cam out ( lose traction on the screw) you risk accidentally damaging whatever medium you are screwing into.

Locally there is an insane institutional preference for the Robertson screw (which is basically a square) because it doesn't cam out much, drives in well and arguably resists stripping better than a Phillips... This is believed in so much that any screw not seen by the camera is a Robby (usually size 2) while anything that is perceived by the audience is a phillips or a single slot screw. Given a choice nobody wants to handle single slots and chances are good you only find them in period specific builds or when the designer is a psychopath.

The only thing slotted was good for was on old ships. When water grime built up on them they were easy to scrape out with your screwdriver and use the screw. That is THE ONLY good thing about slotted screws. If they get full of shit it's easy to clean out. Other than that they fucking suck in every other way.

☝️ this dude screws

Slotted screws are the proof that Satan is real.

Absolutely the only benefit to slot headed screws is how easy they are to make, which is why they're what a home machinist would make when creating his own fasteners, and why any aliens out there that use threaded fasteners have probably also tried and learned to hate them.

Most other shapes of driver aren't cut, they're stamped.

I have never seen a crosshead screw cut out to the edges...

Neither have I but we were talking about how to make a basic screw without needing to forge or stamp or manufacture screws ... if you ever had to make a screw yourself, you take a hack saw and cut a slot in the screw head ... then a second cut crossing the first to make the (+) shape