My first move would probably be to blow my brains out

papalonian

Someone else mentioned gridfinity, that was my first thought too. You can probably find modules for all of the things you listed already made and ready to print.

Once you start with gridfinity, though, you will never stop.

-

You're having an important argument with someone and you're resorting to Reddit for an answer

-

You think having updoots on a Reddit thread matters in a real life argument

-

You want to manipulate an already trashy and biased mediation tool by artificially inflating your position

-

You openly ask for help in doing this with seemingly zero self awareness

If this is real (and I hope to God it's just a shitpost) it's insanely pathetic and abusive. You should not be dating.

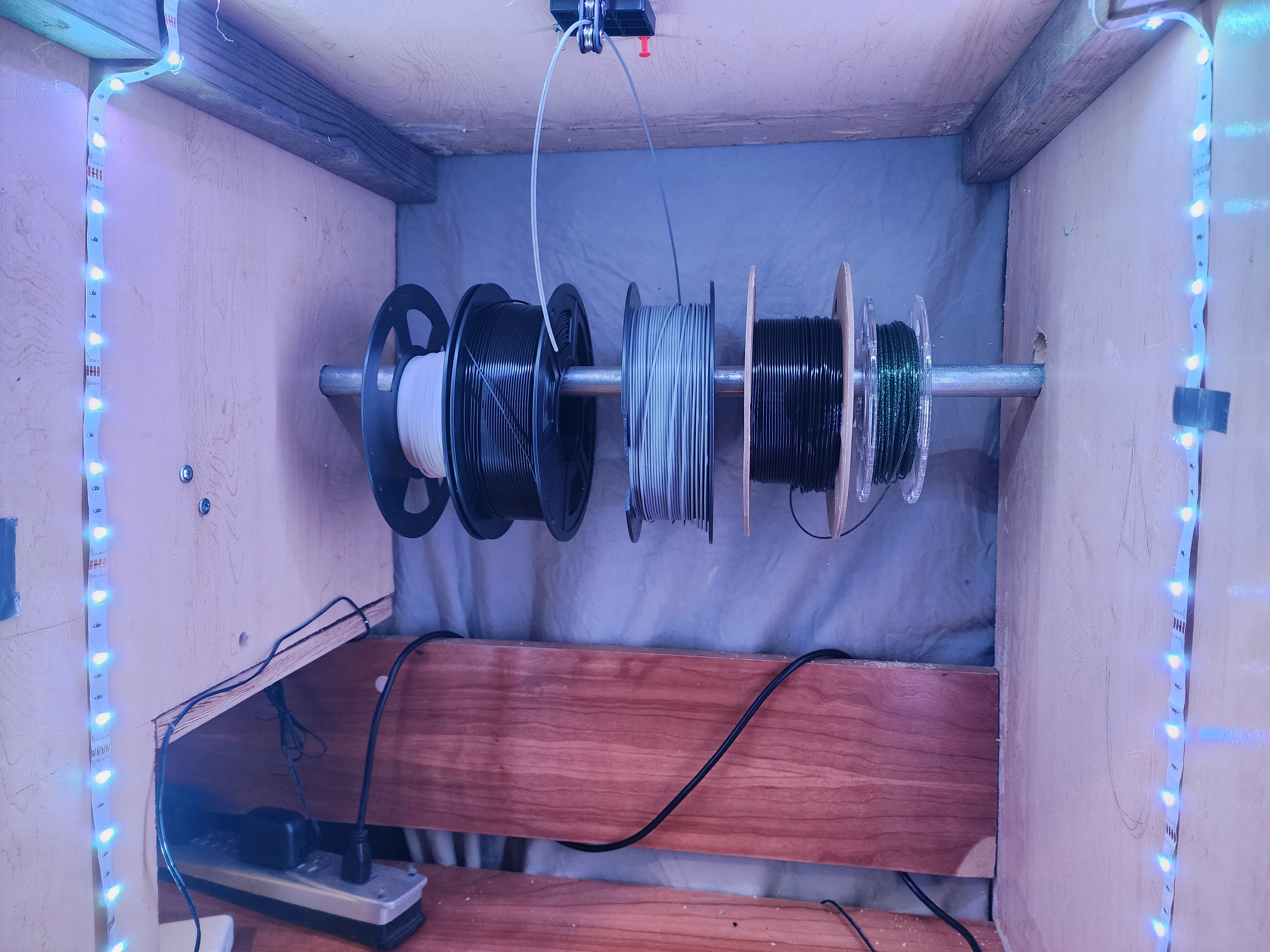

Re: dry. I'm convinced PLA doesn't care about moisture. Watched a video of a guy that soaked a roll in a tub of water overnight, then printed off the roll with it still in the tub. Looked exactly the same as it did before the soak.

Mileage may vary of course but ever since then I've been leaving my PLA out and it's never once given me trouble (the infused ones a little bit).

Well I always wake up where I'm meant to be. When that stops happening I'll stop doing it.

Sorry! The name of the podcast on Spotify is simply, "reading and explaining the Silmarillion".

Sorry, Bilbo. The name of the podcast on Spotify is simply, "reading and explaining the Silmarillion".

There's a podcast done by a well known Tolkien nerd in which he reads The Silmarillion and explains it along the way. I've been slowly making my way through it while driving to work and falling asleep.

"is anyone not from Reddit?"

"Me, I'm from Reddit"

?

Most questions that get posted are the same question but slightly different situation. "Why does my first layer look bad", "what is causing this weird noise", "how do I diagnose this error".

Your use case is interesting. I'll remember it each time I see an update.

Oh ok, I misunderstood some details. That makes more sense.

I'll be here in a year or two for your updates!

I'm a big fan of Emily the Engineer. She's a similar chaotic energy as early Michael Reeves but less directly focused on "offensive ideas" or "things to hurt your friends". The creativity behind both the projects and the videos is top notch.