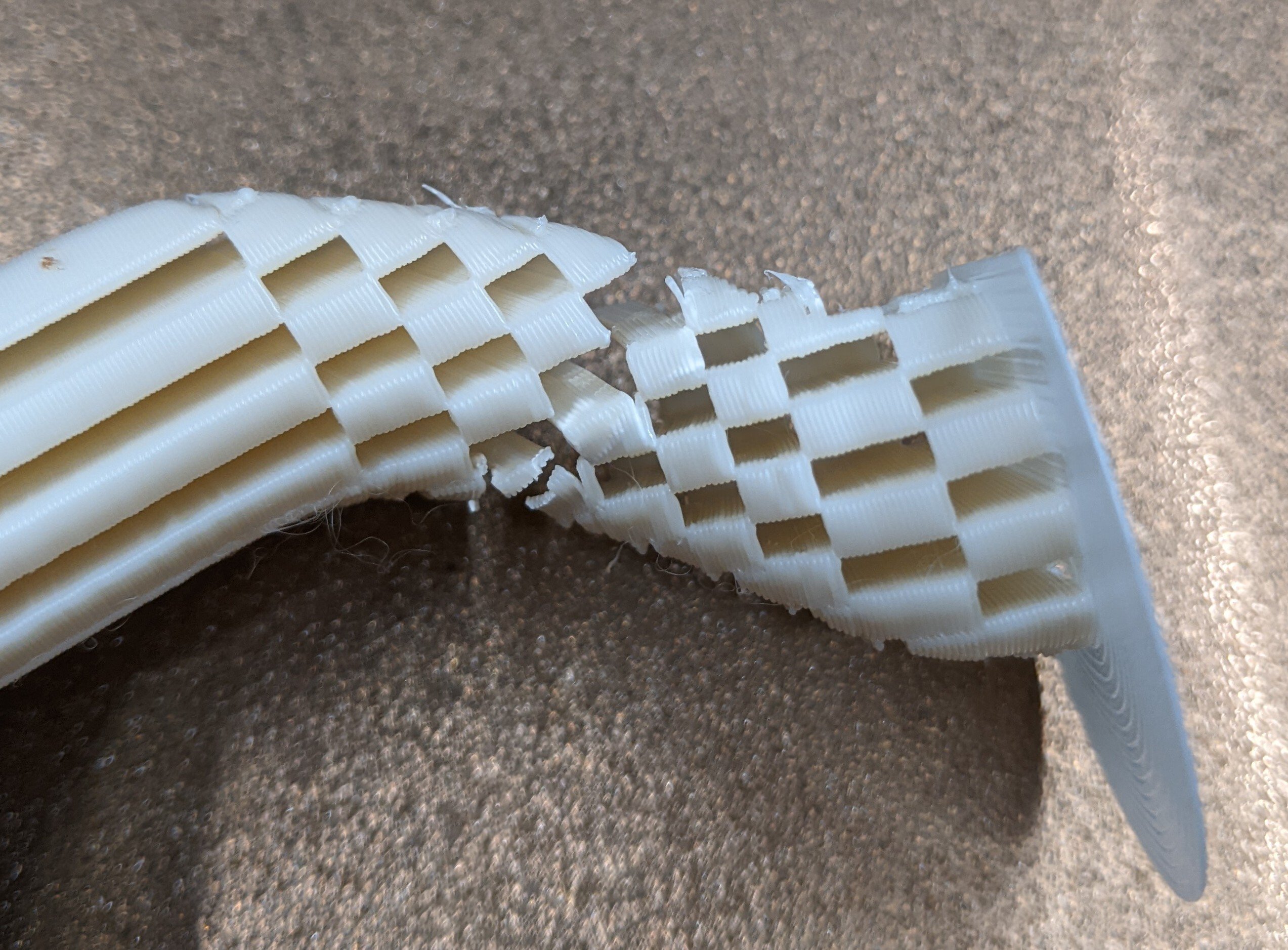

It’s called the ADHD mod

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

That's a fire hazard (in case you weren't already considering it)

The printer is a a Voron 2.4 running klipper with a chamber thermistor, controlled bed fans, and an exhaust fan so it will do a decent job regulating it's temperature. The electronics are outside the chamber and there are acrylic panels under the blanket and hoodies. Should it come to it, klipper has thermal runaway protection. There's also a smoke alarm right next to the printer. I suspect this will be a pretty uneventful print.

I let the printer heat soak for an hour and a half before giving it a go and barely cracked 60 °C, so all should be well. This is a Voron, so the electronics are out of the chamber, have a cooling fan, etc.

Other than looking somewhat janky, this isn't that different than the insulated panels I'll be swapping on to replace the current acrylic panels.

None of this stops the risk of fire.

Once a fire starts, the printer turning off won't magically stop the fire from continuing to grow.

Printers can fail in all manner of ways.

Also, you should have a venting solution of printing ASA.

It's pretty cheap to get a proper fire resistant heat cover for a printer.

Just get an emergency "space blanket", they're often only a couple bucks and quite good, but very fire resistant.

What the holy hell is this nonsense?

You guys will do anything to keep from buying a good printer won't you?

I've done 21 hours prints in my damp cold basement without issue.

You guys make me feel so competent haha.

Imagine feeling so confident to indirectly call Voron a bad printer and tell people how to spend money.

Go get yoursel something to work on instead of mocking other for their temporary solutions.

ASA and ABS are warp prone and this is an 11" / ~275mm wide print that's equally tall 🤷

The build volume of my printer means lots of surface area for the acrylic enclosure, which in turn makes it hard for me to exceed a 50°C chamber temp, despite 4x bed fans.

The next print, with normal supports, pulled the bed off the magnetic build plate. Insulation eliminated warping and let me pull off the print.

I do agree that a "nicer" enclosure is the preferred method. I have zero issues with PETG at this size. I've never tried PLA on this printer, but it should be fine too.