I would try with a brim, but I think it might be an issue with the design not having sufficient material at the base of those walls. The only way to tell is by looking at the sliced file layer by layer.

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

Be respectful, especially when disagreeing. Everyone should feel welcome here.

No porn (NSFW prints are acceptable but must be marked NSFW)

No Ads / Spamming / Guerrilla Marketing

Do not create links to reddit

If you see an issue please flag it

No guns

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

I would try with a brim, but I think it might be an issue with the design not having sufficient material at the base of those walls. The only way to tell is by looking at the sliced file layer by layer.

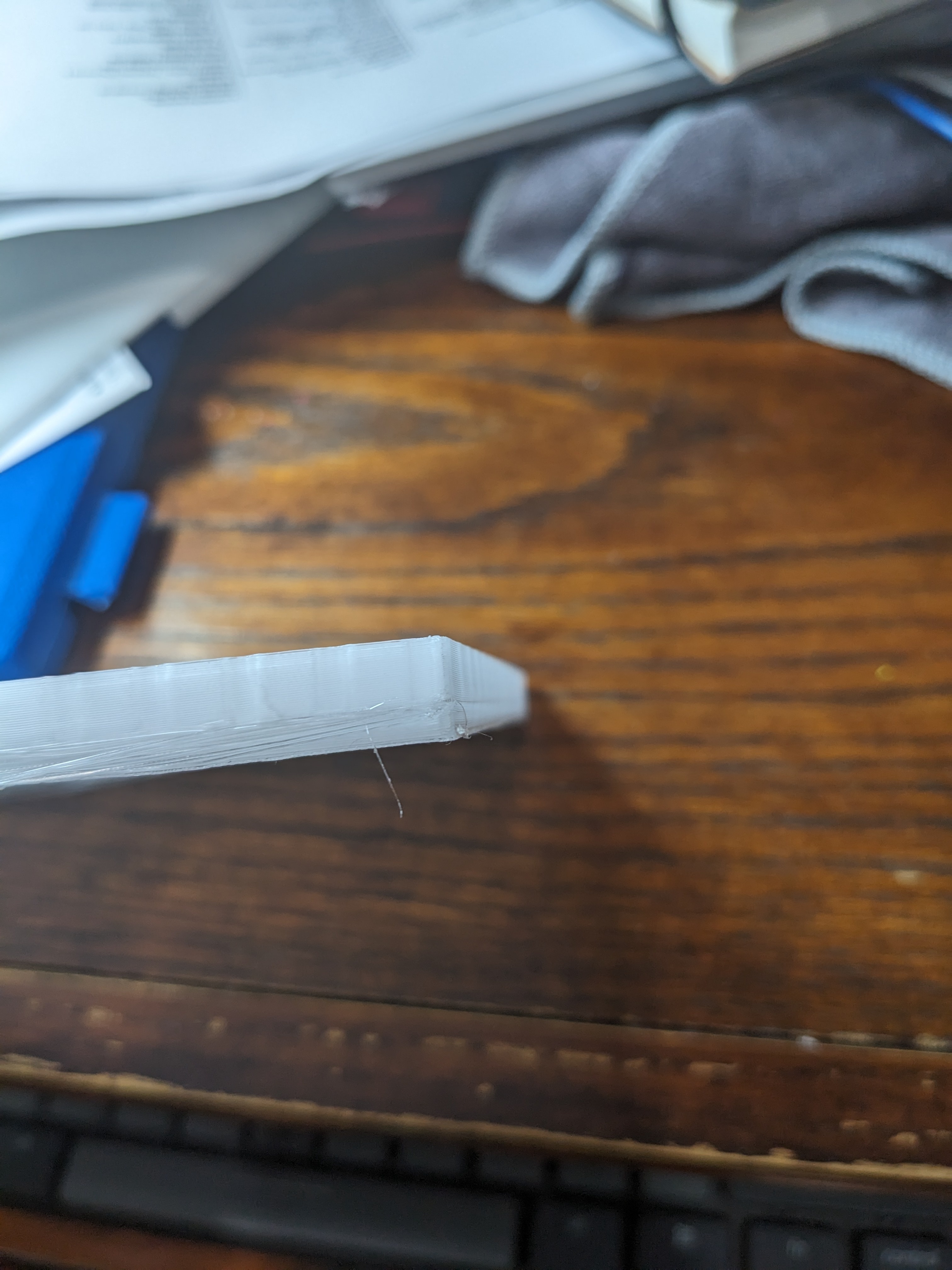

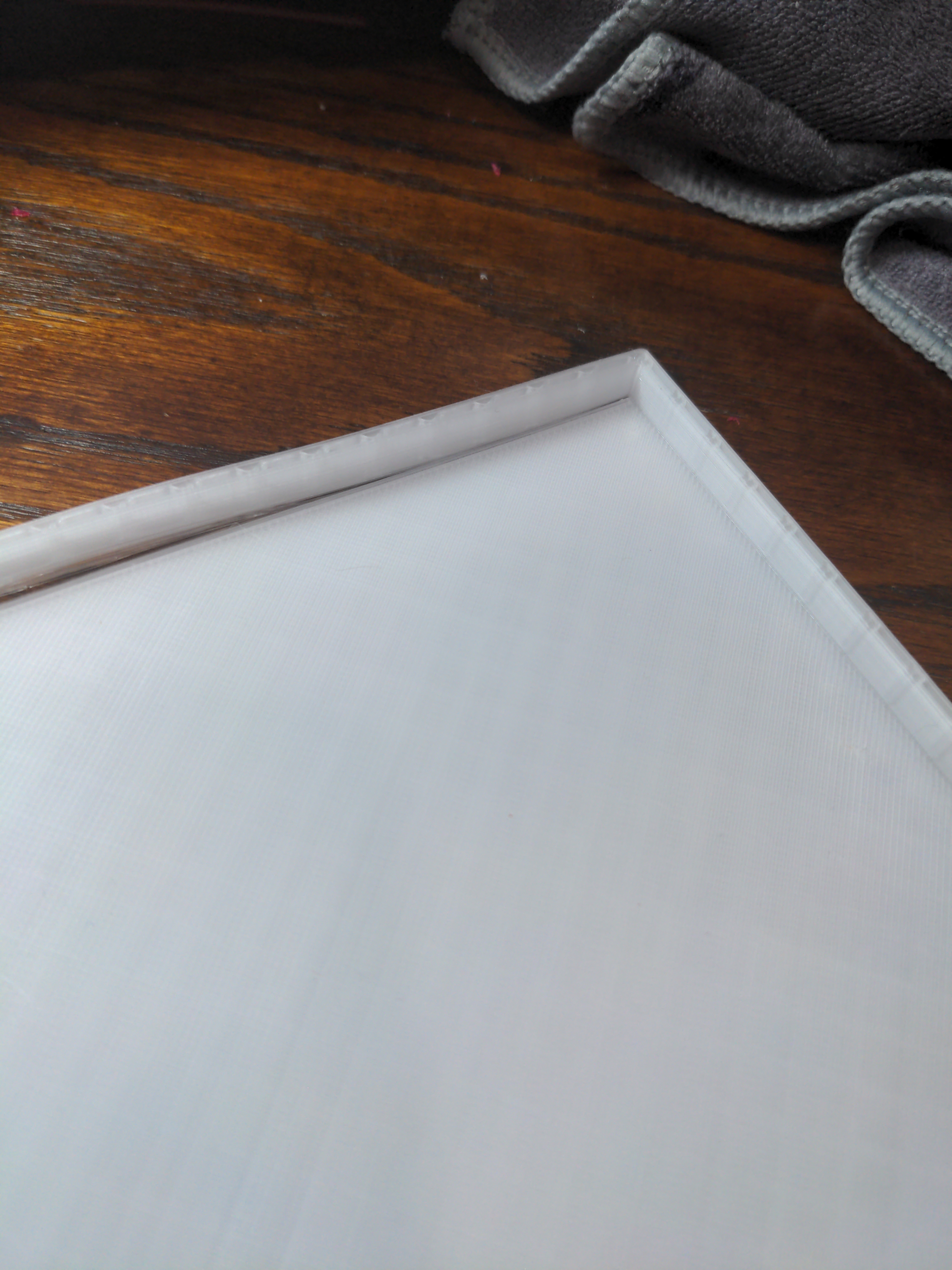

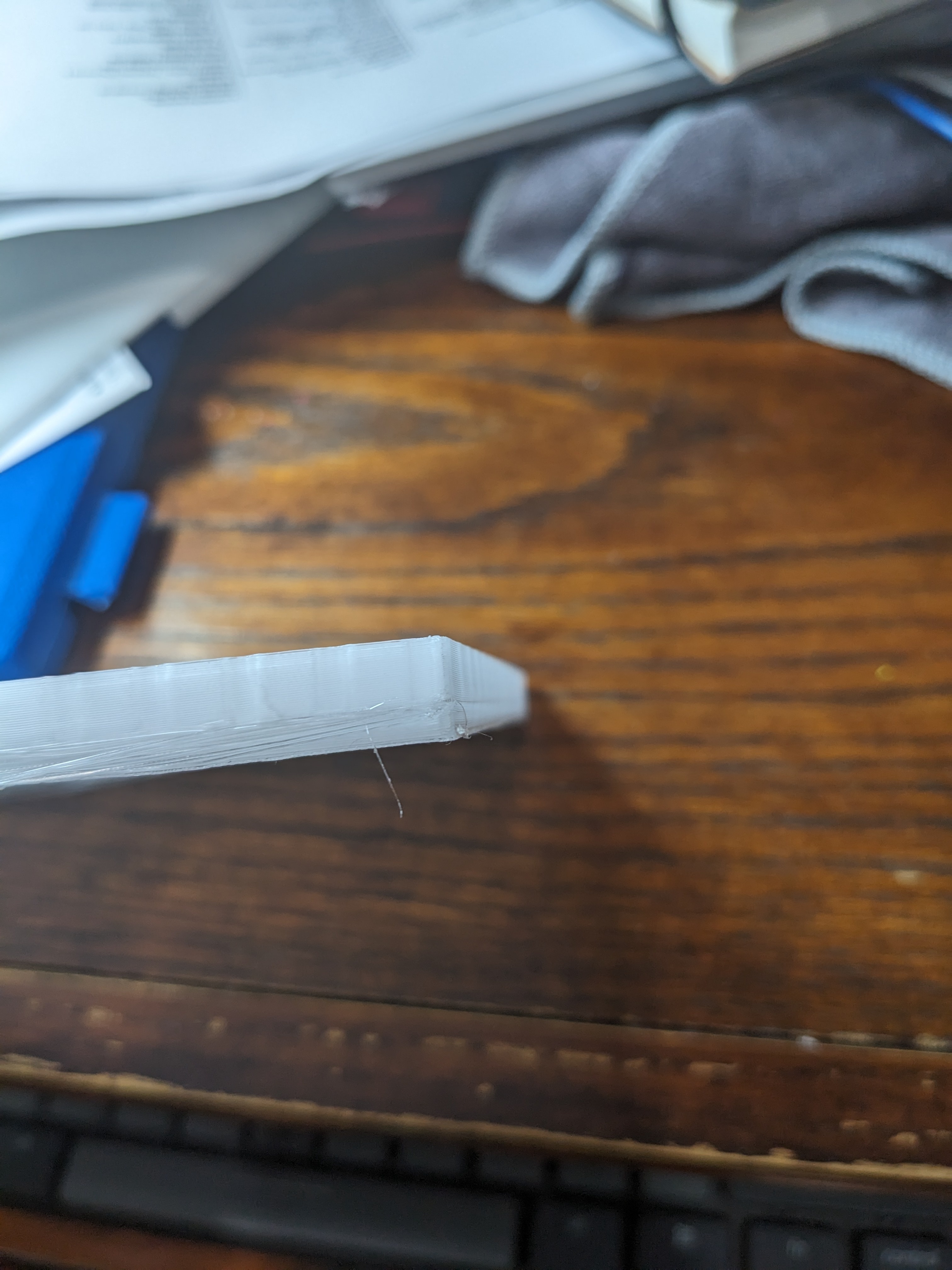

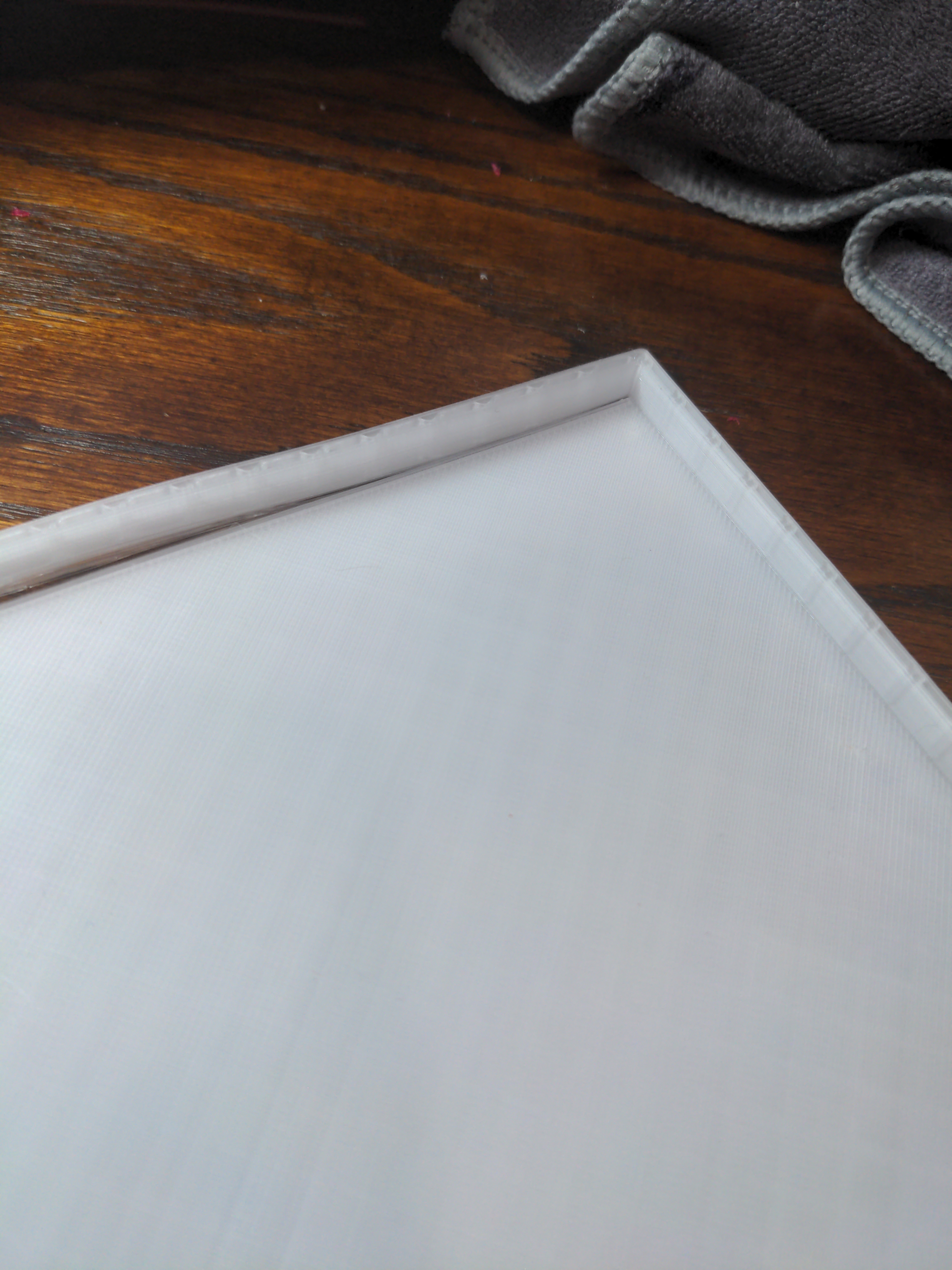

This is the sliced file and my attempt with supports.

A brim will help but the biggest thing is not to use fans at all during the first several layers and very sparingly after that. Also be sure your printer isn't getting hit by a draft from an air vent or open window. PETG warps badly like this from too much cooling/temperature variation.

How much % is sparingly? I'm thinking of turning them off the entire print. It's a pretty large print.

Try with maybe 20-30% speeds after its printed several layers at 0%. You might even try your idea of zero fan the entire time. It'll take trial and error so you may figure out a way to test on a smaller print so you don't waste a bunch of filament.

I'm starting out with 0% first. However, I wonder if it will break my hardware as a device melting plastic at 245 C should have some cooling system or it will burn up right?

typically the fan cooling the heatbreak and extruder stays on even with the "extruder" aka part cooler fan turned off

As the other person stated, the hotend has two fans. One for part cooling and one to cool the extruder itself. The latter is usually controlled by the printer with no way for you to change it (apart from maybe rebuilding your own firmware) so you will be good to go running at 0%. The issue with this is that some part designs need the plastic to be cooled quickly for things like bridging, which is where you'll run into issues having the part cooling fan turned off. That probably won't be an issue when printing a box though.

First things first, check your z offset petg doesn't like being over squished and will lose adhesion because of it. The other thing you should do is ensure your surface is clean, depending on your surface a quick wash with soapy water and a brush is a good idea (some surfaces explicitly say not to do this, my buildtak surface called this out as something not to do), 99% IPA is decent at cleaning between prints but it's a good idea to periodically degrease your surface.

In my experience, adhesion issues with petg have almost always been due to residual oils (fingerprints) or bad 1st layer squish. I print in an enclosure, for me I absolutely require cooling, Prusa's knowledge base is a good place to start as well.

Could be it. I just tried printing again and it wouldn't stick to the bed. I'll try rinsing my bed.

It might just be the specific spool/brand of PETG you used. Try buying some from a major well-known manufacturer, like Overture, Polymaker, etc. I've had cheaper brands shrink, warp, have adhesion issues, and all sorts of other quirks.