3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

I expect you're right, thanks for the sanity check.

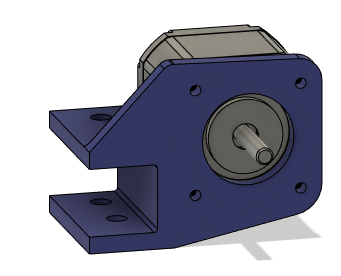

though, the prusa's aren't using printed brackets for the y axis motor mounts, as far as I can tell. I'm guessing that slugging around a print bed and whatever is being printed might cause it to Need replacement- but probably not "frequently". Infrequently enough at least that I can help the kid through it. (So, the friend is maybe an ~~idiot.~~ not-engineering-minded)

If you're concerned about durability, you could potentially add in some bolts to use as a slip-in rigid spine to further reinforce the design. I'm thinking something similar to how concrete is tensioned to provide rigidity and strength.

I'm spitballing ideas to see if I can spark something workable for you.

Check the mk3s printable parts , every motor on the mk3 is mounted using printed brackets, abs/Asa holds up really well and honestly petg does as well, I had a petg failure on my x axis after doing days of enclosed abs printing which says a lot considering it was easily 50+ deg c in the enclosure. I've since put probably a few thousand hours since rebuilding with abs and have had no issues with the printed parts.

Vorons also use printed motor mounts and they also hold up with high enclosure temps for extended periods

RatRig V-minion uses printed (ASA/PETG) parts for all motors, and 10k mm/s² acceleration is normal. Granted, a smaller bed slinger, but still.

Vorons use 3d printed mounts for all of their motors for another reference (5 perimeters and 40% infill iirc). I think it would be fine given you're using asa/abs and maybe thicken the bracket model up a bit where the motor mounts if you want.