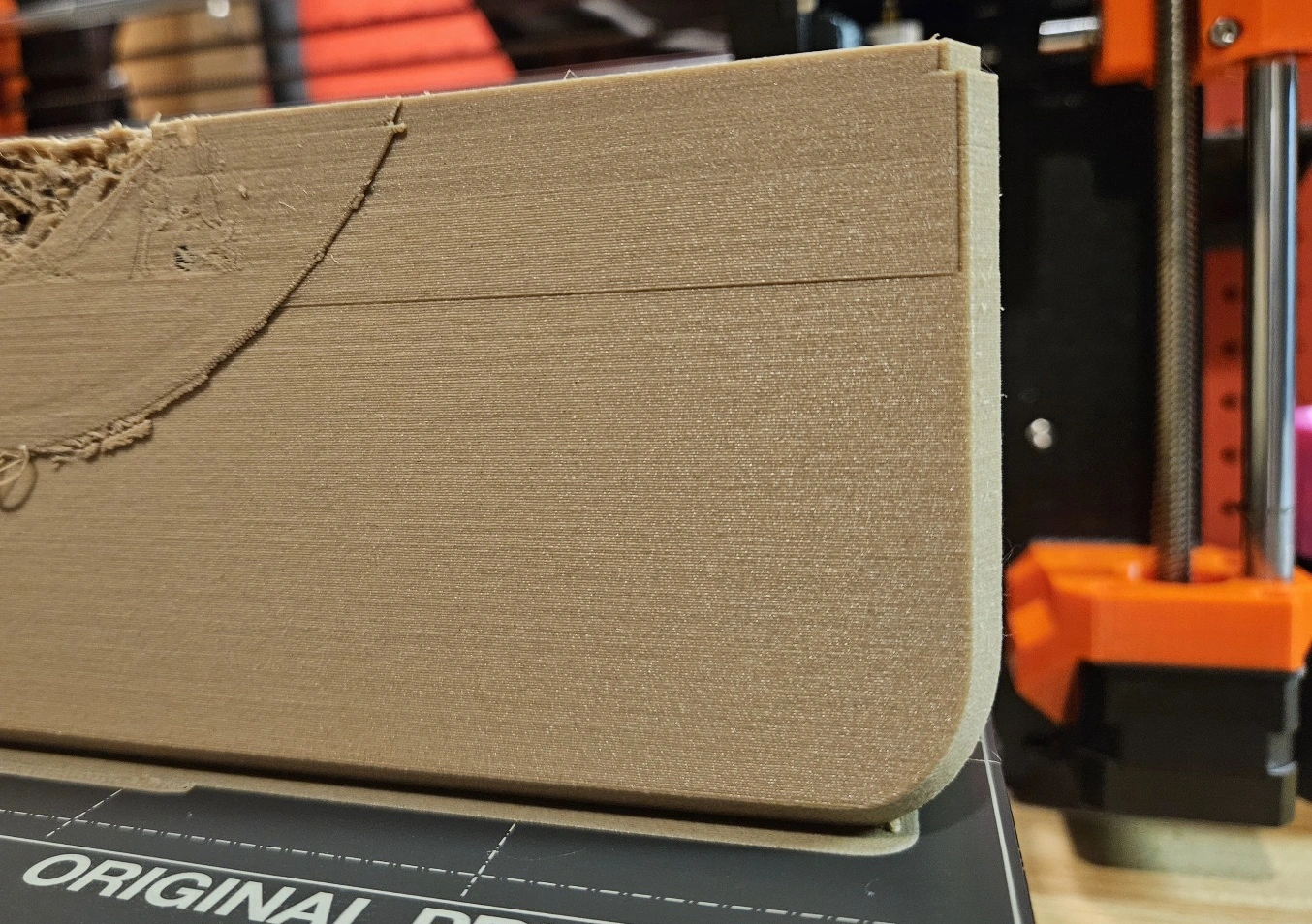

Had slipping issues for taller prints as well. Brought the print speed way way down and it seemed to work.

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

It's a 48h print with variable print speed. I wonder if the variable speed threw it off somehow. I will check my belt tension. Will be a little disappointed if that's already off since it's a fairly new printer. Will try the reprint without variable speed and maybe I'll simplify the design elements a bit.

If belts are tensioned not too tight and not too loose;

The next thing to look at is the drive gear on the x motor- if it’s a bit loose, it could slip.

Another thing is the hotnend mount- if it’s Loose it can wiggle back and forth as it drags on the part.

Then, finally; if none of those seem off; check the x motor itself for voltage and overheating.

Belt tension should be checked regularly and definitely before printing on a new machine. It being new doesn't have anything to do with belt tension.

Belts being too tight is just as much of a culprit as belts being too loose. Tension your X axis belt correctly.

It looks very close to the edge of the print bed. Is there any chance the print head crashed into the side and made the belt slip? Something like this?

Here is an alternative Piped link(s):

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I'm open-source; check me out at GitHub.

Are all belts on the printer tightened properly? Did you print via Octoprint? Sometimes this may happen if there's a short network / WiFi issue. Can also happen with some brands of SD cards. So if you have another one available that might be worth a try.

And can't you save your print by simply grinding off the superfluous filament? If parts are missing you might also add some glue or putty to fill the gaps. If visual appearance is important for your part you could also apply some spray paint or acrylic paint.