3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

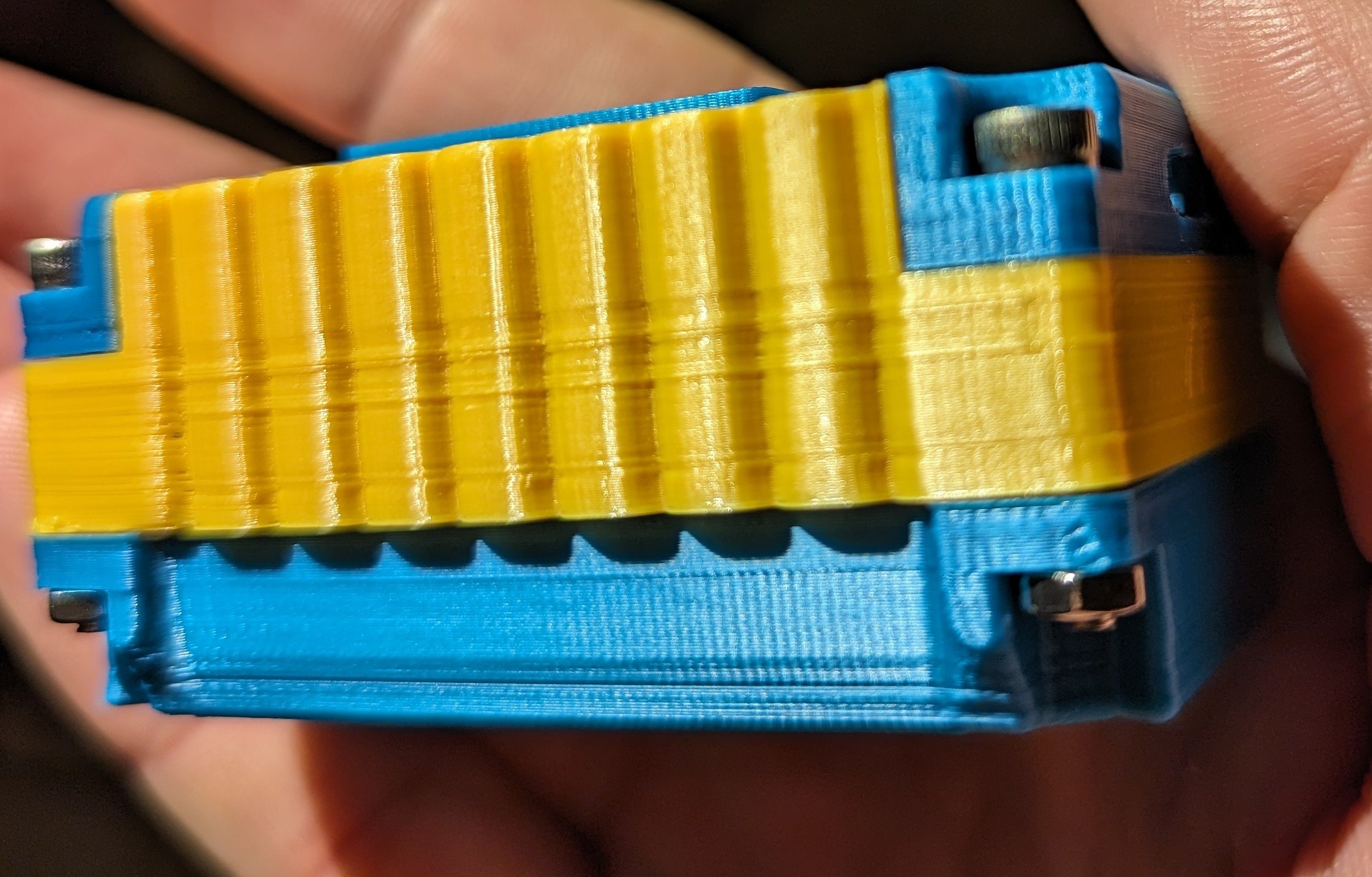

Good point. I knew it had to be something systematic, but didn't really know where to check from there. Here is the left side and here is the right.

Sorry for the late reply, tied up. Thankyou for the photos.

The Z-axis leadscrews look OK in the photos (nothing obviously wrong). That's a very clean and new printer.

Q1. Is there any grease on those Z-axis leadscrews (tall metal spiral rods) or are they completely dry?

Q2. If you force your printer to move up and down does it make unusual noises at some parts of its travel height? You can try typing thing g-code into your printer monitor software to make it move up and down:

You may need to home the axes first (G28)

Q3. Are these screws on both sides properly tight? I think I might possibly see a gap under one, but it could also be an optical illusion from reflections.

Thank you, and no worries on the late reply. I'll check all of this soon. You are right in there being a small gap there. It is normally tight, however I did loosen it a smidge because someone in a video mentioned that might add some forgiveness if one of the screws (or leadscrews as I'm learning) is not true.

Those screws are/ were dry though. I recently put a small amount of WD-40 onto a paper towel and cleaned them up a bit (maybe not the best choice vs a machine oil or something similar).