3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

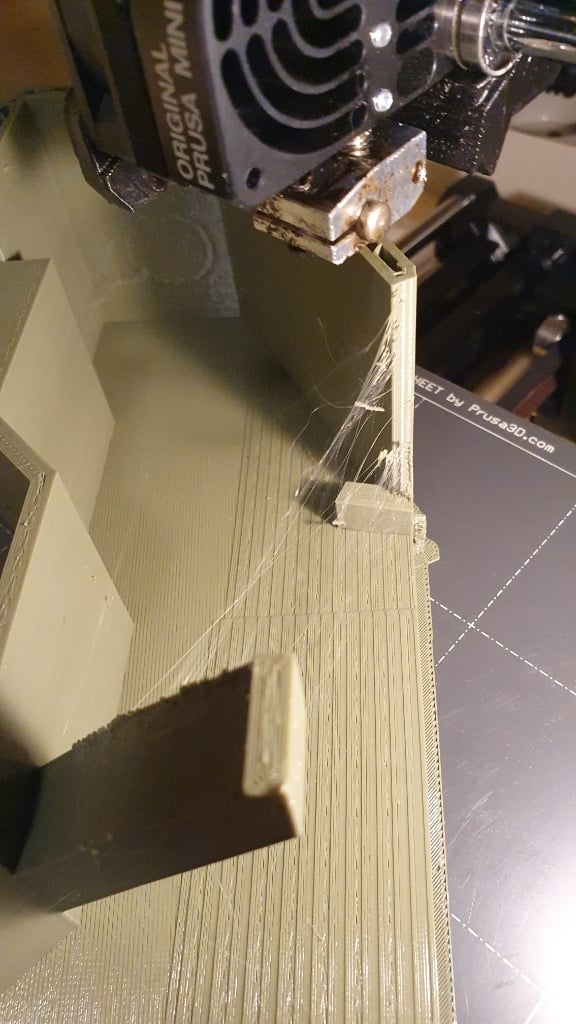

Often a combination of temp too high, not enough retraction, or water contaminated filament.

If the plastic in the hot end is too hot it will keep "running" out of the nozzle after retraction and you'll get strings. Similarly if you don't retract enough to actually pull plastic out of the nozzle during a rapid move, it will want to keep pushing thru. This is supported by the little blobs it leaves on that angled surface corner its travelling to when stringing, thats excess material squeezing out during its rapid moves then being left on that wall.

And if there's water in your filament all bets are off on how it'll behave.

215 is pretty warm for that esun PLA especially if you're using the stock brass nozzle, try bumping that down to 205 or even 200, and increase your retraction speed and distance settings in prusaslicer a tiny amount (0.1mm distance, 2mm/s speed at a time until you see improvement is plenty)

Use a temperature calibration tower to test things out.

This guy 3Dprints.

What a treat of a post. This is why I subscribe to !3dprinting@lemmy.world. Thank you.

Hell yeah I do. I help run the makerspace at my college. I've fixed damn near every problem a Prusa can have at this point lol

Great advice

Thank you! <3 The print finished and now I am running a temp tower to check what works better than what I had. I would then work on adjusting the retraction, too. Also, this filament is straight out of the factory wrap so it should be dry enough.

Glad to help, and good luck! This is only the first step into becoming a master print tuner.

Something else that contributes to stringing is using Z-hop as there's nothing to wipe the nozzle clean. My printer is calibrated well and I still get stringing when using Z-hop.

Based on the layers of his print I'd say he also needs to level his bed